What Is Glue Dispenser

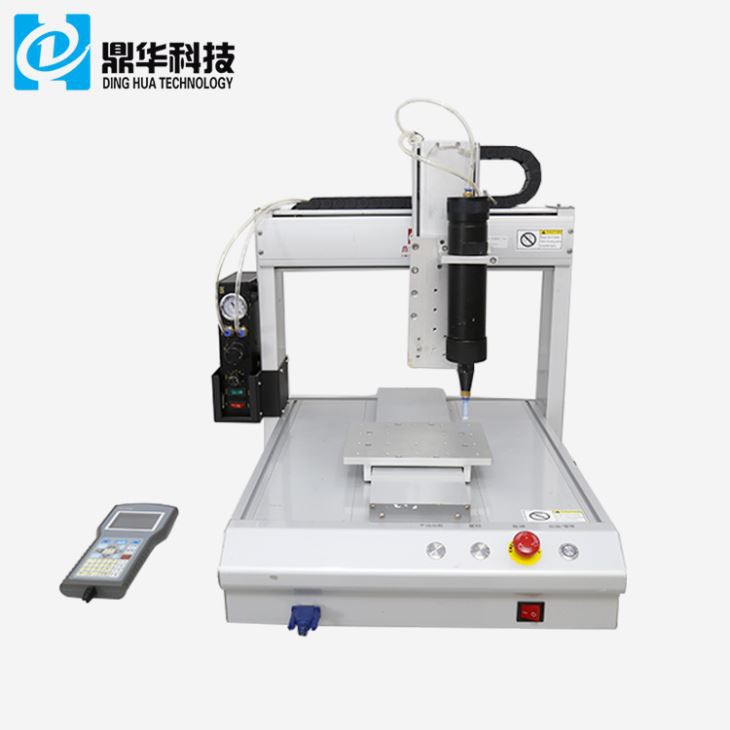

Glue dispenser, we also call coating machine ,glue potting machine and so on. It is a flow controlling system. The automatic glue dispensing machine dispense or coat the glue on the surface or internal of the products which can be 3D/4D track. The functions including accurately positioning, precision glue controlling, no drawing, without leakage and so on. Glue dispense main widely use for dot, line, arc, circle track to accurately dispense glue, oil paint or other liquid to each product .

Advantages of Glue Dispenser

Smooth and fast dispensing

Not only is the dispensing process unobstructed, but the finished product is beautiful and flawless, and the processing effect of glue pulling and fluid bubbles is faster and more complete, so the composition of the automatic dispensing machine is more rigorous.

Equipped with guide rails to improve fluency

The guide rails of the automatic dispenser are made of stainless steel. The corrosion resistance of the rail is better than that of stainless steel. It can be used in high pressure environment for a long time. The robotic arm works, so the robotic arm moves very smoothly during dispensing work.

Materials that make up the fuselage improve durability

The body of the automatic glue dispenser adopts aluminum alloy sheet as the frame. It has corrosion resistance and impact resistance through cold working, and can avoid the influence of adhesives, so the working environment conditions of automatic glue dispensers are relatively low.

Accurate

Highly accurate dispensing and extruding nozzles. Equally accurate positioning system for precise glue placement. Real-time visual quality control using onboard cameras.

-

The top quality, stable performance, cost-effective automatic glue dispenser Supplied by the 9

Add to Inquiry -

The top quality, stable performance, cost-effective glue dispenser robot Supplied by the 9 years

Add to Inquiry -

The top quality, stable performance, cost-effective glue dispenser valve Supplied by the 9 years

Add to Inquiry -

The top quality, stable performance, cost-effective glue dispenser valve Supplied by the 9 years

Add to Inquiry

Why Choose Us

Professional team

Our professional team collaborates and communicates effectively with each other, and is dedicated to delivering high quality results. We are capable of handling complex challenges and projects that require our specialized expertise and experience.

High quality

Our products are manufactured or executed to a very high standard, using the finest materials and manufacturing processes.

Advanced equipment

A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

Competitive price

We offering a higher-quality product or service at an equivalent price. As a result we have a growing and loyal customer base.

Customized services

We understand that each customer has unique manufacturing needs. That’s why we offer customization options to cater to your specific requirements.

24H online service

We try and respond to all concerns within 24 hours and our teams are always at your disposal in case of any emergencies.

Glue Dispenser Is Key Components in the Manufacturing Process of Various Products

Glue dispensing equipment is a critical component in the manufacturing process of various products, ranging from electronics to automobiles to medical devices. There are three main types of glue dispensing equipment available in the market, each with its own set of advantages. Manual applicators are basic, handheld tools that allow operators to apply glue to products by squeezing a trigger or pressing a button. They are easy to use and affordable, but may not be suitable for high-volume production. Manual applicators work by using a flexible tube and a pinch mechanism to control the flow of adhesive through the system. The operator manually controls the flow of adhesive by squeezing the trigger or button, and the adhesive is applied to the desired area. Metering systems are more complex glue dispensing machines that use positive displacement pumps to accurately meter and apply adhesive. They are suitable for high-volume production and can handle a wide range of adhesive types and viscosities. Metering systems use a positive displacement pump to accurately measure and dispense the adhesive. The adhesive is drawn into a reservoir, and then a piston or gear mechanism applies pressure to the adhesive, forcing it through a metering valve and out of the dispensing tip. The flow rate is controlled by adjusting the stroke length or speed of the pump.

Glue dispensing equipment is used in a wide range of industries, including automotive, electronics, and medical devices.Bonding is the process of using adhesive to join two or more parts together. The adhesive is applied to the surface of the parts, and then the parts are pressed together until the adhesive dries or cures. Bonding is commonly used in industries such as automotive, aerospace, and construction to join materials such as metal, plastic, and composite materials. Bonding offers several advantages over other methods of joining, including improved strength and durability, reduced weight, and increased design flexibility. Coating is the process of applying a thin layer of adhesive to the surface of a product to improve its performance or appearance. The adhesive is applied using a spray gun or other dispensing equipment, and then it is allowed to dry or cure. Coating is commonly used in industries such as electronics, automotive, and consumer products to protect the surface from damage, improve adhesion, or enhance the appearance of the product. Sealing is the process of using adhesive to fill gaps or cracks in a product to prevent the leakage of fluids or gases. The adhesive is applied to the surface of the product, and then it is allowed to dry or cure. Sealing is commonly used in industries such as automotive, aerospace, and electronics to seal joints, seams, and other areas where leakage may occur. Sealing offers several advantages over other methods of sealing, including improved strength, durability, and chemical resistance. Potting is the process of completely encapsulating a product or component in adhesive to protect it from external factors such as moisture, dust, and vibration. The adhesive is poured or injected into a container or mold that surrounds the product or component, and then it is allowed to dry or cure. Potting is commonly used in industries such as electronics, medical devices, and aerospace to protect sensitive components from harsh environments. Potting offers several advantages over other methods of encapsulation, including improved protection, reduced weight, and increased design flexibility. Encapsulating is the process of using adhesive to completely encapsulate a product or component to protect it from external factors such as moisture, dust, and vibration. The adhesive is applied using a dispensing equipment, and then it is allowed to dry or cure. Encapsulating is commonly used in industries such as electronics, medical devices, and aerospace to protect sensitive components from harsh environments. Encapsulating offers several advantages over other methods of encapsulation, including improved protection, reduced weight, and increased design flexibility.

Selection Criteria for Glue Dispenser

The right equipment can ensure optimal performance, increase productivity, and reduce waste. However, selecting the right glue dispensing equipment can be a challenging task, as it involves considering several factors such as adhesive type, viscosity, and application requirements.The type of adhesive used in the manufacturing process is an essential factor to consider when selecting glue dispensing equipment. Different adhesives have varying properties, such as viscosity, curing time, and chemical composition. Fast-curing adhesive used for bonding metals, plastics, and rubbers. Two-part adhesive used for bonding metals, ceramics, and composites. Fast-curing adhesive used for bonding plastics and metals. Flexible adhesive used for sealing and bonding in high-temperature applications. The viscosity of the adhesive is a critical factor to consider when selecting glue dispensing equipment. The viscosity of an adhesive refers to its thickness or resistance to flow. It is measured in centipoise (cps). The selection of the appropriate pump depends on the adhesive viscosity and the required flow rate. Suitable for manual applicators or low-pressure dispensing systems. The application requirements of the product are another critical factor to consider when selecting glue dispensing equipment. Factors such as the desired flow rate, pattern, and precision of the application must be considered to ensure optimal performance. Different types of equipment, such as manual applicators, metering systems, and robots, offer varying levels of precision and control. Material compatibility is another crucial factor to consider when selecting glue dispensing equipment. The equipment must be compatible with the materials used in the manufacturing process to ensure optimal performance and prevent damage to the product. The equipment must also be resistant to the chemicals in the adhesive. It is important to select equipment made from materials such as stainless steel or PTFE, which are resistant to most chemicals.

Automation of adhesive dispensing has gained massive popularity in recent years thanks to the productivity and efficiency advantages they provide in a plethora of applications. Even though adhesive dispensing systems require a hefty initial investment, as well as additional mechanical systems to position and hold objects for dispensing in a repeatable fashion, manufacturers are still seeing the returns they need with these systems in the long run. In some instances, they have the potential of cutting cycle time in half. By nature, robotic systems are highly cyclic. The adhesive dispensing process becomes highly accurate after automating. Minimal time is spent perfecting and cleaning up incorrect and messy dispensing jobs. The production line can thus move as fast as the adhesive can be dispensed. Robots can dispense adhesives extremely fast. Certain systems are known to dispense at speeds up to 800 inches per minute (IPM) with almost perfect accuracy. Add high levels of uptime to this, and you have an automated dispensing system that can outdo your manual processes by a huge margin. The way these robotic technologies have become so successful is by designers performing experiments on customer products to ensure they are providing and building an accurate robot dispensing technology that will give the best results possible. Because these robots provide such high-quality products, it is no wonder why they are ideal solutions for adhesives and bonding in various industries. Aerospace adhesive is applied throughout the entirety of the interior, exterior, and engine compartment of aircraft. Usage varies from overhead lockers to the handy seat trays and even the in-floor lighting. From consumer goods, industrial manufacturing, or compounding, adhesive products provide reliable, efficient, and innovative solutions to all bonding challenges. Adhesives employed in medical practices are most commonly used for surgical procedures and appliance bonding, and while medical adhesives encompass a wide range of fabrication materials, they are typically composed of synthetic or biological formulations. Adhesives can be used throughout the lighting industry. Electronic PCBs and lamp holders require bonding to hold them in place. Light reflectors need bonding – sometimes high-temperature adhesives are necessary to cope with extreme temperatures for this type of application, usually for industrial lighting and stage and theatre lighting where high-powered bulbs radiate a lot of heat. Adhesives and sealants are used by car and truck manufacturers to bond and seal their vehicles’ interiors, exteriors, under the hood, under chassis, and many other related applications. The printed wiring board or, as it is more commonly referred to, the printed circuit board (PCB) is the core building block of the electronics industry. The PCB utilizes adhesive materials in bonding surface-mount components, wire tacking, conformal coatings, and encapsulating (potting) components.

The Difference Between Glue Dispenser and Glue Potting Machine

While both glue dispensing machines and glue potting machines are used in industrial and manufacturing settings for adhesive applications, they have some differences in their functionality and applications. Glue dispensing machines are designed to accurately and precisely apply adhesive materials to specific locations on a part or surface. These machines use a variety of application methods, including spray, needle or nozzle dispensing, and jetting. They are typically used in applications where a small amount of adhesive is required at a specific location or where a high level of precision is needed. They are commonly used in electronics, automotive, and medical device manufacturing.On the other hand, glue potting machines are designed to fill entire cavities or enclosures with adhesive material. They are typically used in applications where a part or assembly requires a high level of protection from environmental factors such as moisture, dust, or vibrations. Glue potting machines are used to apply a thick layer of adhesive to enclose and protect sensitive components such as circuit boards, sensors, or electronic assemblies.While glue dispensing machines and glue potting machines share some similarities in their application of adhesive material, they are typically used for different purposes and in different types of applications. In general, glue dispensing machines are used for precise, small-scale adhesive applications, while glue potting machines are used for large-scale applications where a high level of protection is needed.

Why Do You Need Adhesive Glue Dispenser

A glue dispensing machine is a device that dispenses adhesives in precise amounts. This kind of machine is often used in manufacturing and assembly lines to apply adhesives to products consistently and accurately. In a few ways, adhesive dispensing systems save money and time. For one, they are precise and uniform in their adhesion application. This means that less adhesive is wasted, which may help you save money. Second, glue dispensing machines are quick and efficient. This means that items can be put together faster, saving labor costs. Finally, they require very little maintenance. This means that the company can spend less time and money on upkeep and repairs. Glue dispensing machines can be used in many different industries of various adhesive applications. Some of the most common industries include electronic manufacturing services (EMS), LED manufacturing, packaging, automotive manufacturing industry, and any other industries that require repeatable and accurate glue dispensing processes.

Our Factory

Shenzhen Dinghua Technology Development Co., Ltd. is a national high-tech enterprise integrating R&D, production, sales and service! Which is a professional BGA rework station, automatic soldering machine, Xray inspection machine, U-shaped line transformation and non-standard automation system solutions and industrial equipment providers! The company is "based on research and development, quality is the core, service is the guarantee", and is committed to creating "professional equipment, professional quality, and professional service"!

FAQ